How To Remove Rounded Edges On 2x4

Hither's everything you lot need to know about 2x4 lumber! What are the actual dimensions of a 2x4, the all-time saw to cut 2 by 4 wood, what screws to use in a 2x4 and project ideas to get yous started!

2x4 studs are one of the cheapest and easiest sources of lumber for showtime woodworkers. But if you've never congenital annihilation before, at that place's a lot to learn! In this guide, I'll answer all your questions nigh the humble 2x4 and help you become started on your next project!

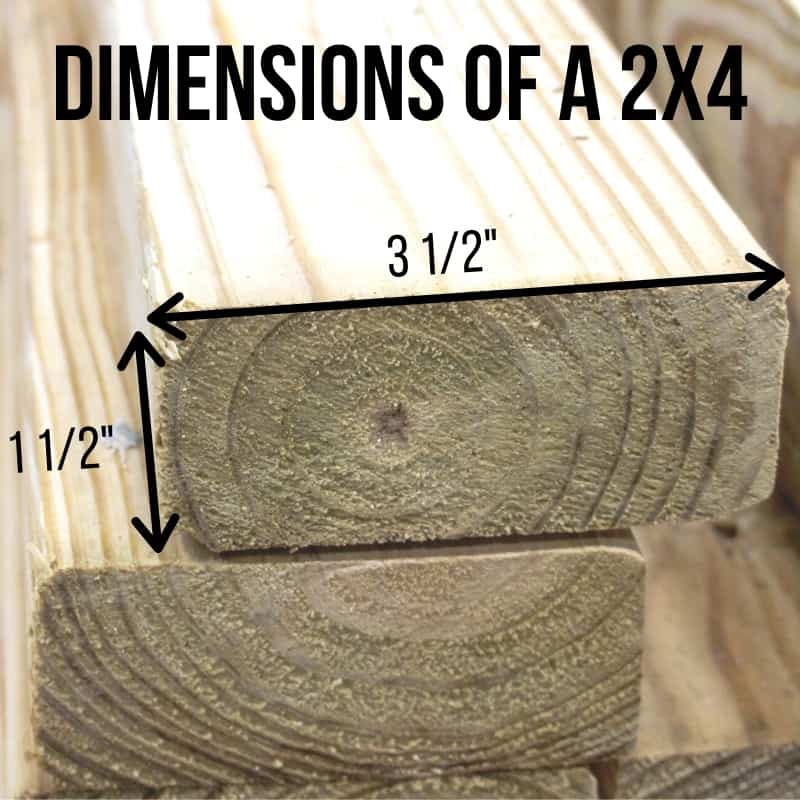

What are the bodily dimensions of a 2x4?

Believe it or not, a 2x4 board does Non measure 2" ten 4"! The actual dimensions of a 2x4 are ane ½" thick and 3 ½" broad. What?!? Why is a 2x4 not ii" ten 4"?

Actual size vs nominal size

2x4 lumber is made from a diversity of softwood species. Dorsum in the day, each mill cut down their logs into boards that were roughly ii" x 4" (the nominal size) but the surfacing and drying process was dissimilar at each location, resulting in an assortment of actual finished sizes.

Over time, the size of a 2x4 shrunk in order to compete with other building materials. Mills were trying to get more boards out of a single log, and charge the aforementioned cost. Eventually, the actual size of a 2x4 was standardized at i ½" x three ½" to continue the dimensions consistent throughout the industry.

You can read more about the history of the 2x4 here.

Standard 2x4 length

2x4 studs are typically eight anxiety long, to match the standard length of a sheet of plywood or drywall. You can also find 2x4 studs that are 92 ⅝" long, which allows builders to account for the thickness of the boards that run along the peak and bottom of the wall.

Pay attention to the lengths listed on the lumber bin when buying 2x4s for a projection! My woodworking plans e'er call for 96" long boards, and grabbing the wrong size may mean an extra trip to the store for more supplies!

In addition to the standard 8 foot length, yous can also observe 2x4 boards in 10, 12, xiv or even sixteen pes sizes. But these are well-nigh impossible to send home in my motorcar, so I stick with what fits in my pocket-size SUV!

What to look for at the lumber thou

Venturing into a lumber chiliad or the lumber section of the dwelling comeback store for the showtime fourth dimension can exist daunting! There are so many stacks to choose from! Just grab a lumber cart and wander until you've constitute the 2x4s you're looking for.

Avert cracked and damaged boards

When yous finally find the pile of 2x4s, y'all'll probably encounter a agglomeration of cracked and damaged boards right on top. These bins get picked through all the time, and the worst ones are left behind. Don't grab boards right off the top!

Dig downwards or back a few layers until you see all the tightly packed 2x4s all neatly arranged in stacks. These are the boards that haven't been picked over, and there'south bound to be some great ones in there! Sometimes there will be a band around a new shipment of lumber, and I'll utilize my automobile keys to cut the band and pull out all the skillful stuff.

Set aside any 2x4 lumber without cracks, missing chunks and deep scratches. I'chiliad usually pretty picky and volition avoid as many knots as possible to save myself some work afterward on.

Expect for bowing and cupping

2x4 lumber is cutting and milled speedily, and unremarkably isn't given a lot of time to dry out. As a result, the boards you find at the store can exist cupped and bowed. This isn't a deal-breaker in structure, but a straight lath is absolutely necessary for building furniture!

Take a quick wait at each board yous picked out. Set up one end down on the floor, and bring the other finish upward to your centre. Sight downward the length of the 2x4 to see if it'due south straight. You tin can usually tell right away if it's curving off to the side. I've seen some that would make a great canoe! 😉

You should likewise look at the ends to see if the corners are xc degrees and straight. If it'southward shaped like a murphy chip, information technology's cupping! This is more mutual in wider boards, but it doesn't hurt to check.

Once you have the best 2x4 lumber picked out, you can get it cut downward into shorter lengths at the store to make it easier to get information technology dwelling. It tin be catchy to fit 8 foot boards into a compact car, and not everyone has seats that fold completely apartment like this! 😉

How to cut a 2x4

You can utilize pretty much any saw to cut a 2x4, simply some will do a better job than others. Outset, allow'southward talk about the two different types of cuts you tin can make.

Types of cuts

A cross cut severs the fibers across the grain, making the 2x4 board shorter. This is the near mutual type of cut, and can be made with nearly saws.

A rip cut slices downwards the length of the board with the grain. This makes a thinner board, and is commonly used to take off the rounded corners of standard 2x4 lumber. It's difficult to brand a rip cut with annihilation other than a tabular array saw, although information technology'due south possible to do it with a circular saw with the correct back up.

How to cut a 2x4 without ability tools

If you desire to cut a 2x4 without power tools, endeavor a miter box with a manus saw. The slots in the box will help guide the saw to create a directly cutting while y'all pull the teeth back and along beyond the board. You tin can acquire more most how to use a miter box hither!

How to cutting a 2x4 with a round saw

Most homeowners have a round saw gathering dust in their garage (or if yous're like me, you shop it on this handy circular saw rack!)

It's pretty like shooting fish in a barrel to brand a straight cut beyond a 2x4 with a round saw simply by lining up the blade with the cutting line. Belongings a speed square next to the base plate will help guide the saw directly. You can besides use a jigsaw to cut a 2x4 the aforementioned style!

Simply for the nearly precise cuts, I recommend making a round saw jig that you can clamp to the board correct where you want it. Yous tin can even make rip cuts with this type of jig, so long as the saw is supported properly and doesn't tip.

How to cut a 2x4 with a miter saw

The easiest style to cut a 2x4 is with a miter saw. It tin can make direct cross cuts as well as angled cuts just by adjusting the blade. If you fix upward a stop block system, you can create a stack of identical 2x4 pieces in minutes!

The miter saw is perfect for making cantankerous cuts, but it's not safe for making rip cuts. Your fingers will be way too close to the spinning blade for comfort. Yous tin can acquire all about how to use a miter saw in this guide!

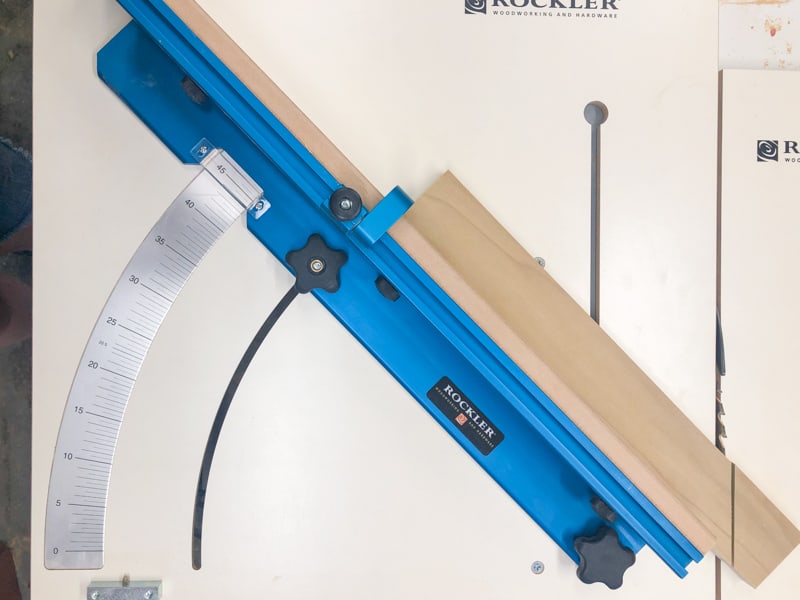

How to cut a 2x4 with a table saw

A table saw tin can make both cross cuts and rip cuts with ease. I usually employ the table saw to trim off those rounded corners on the 2x4, or cut it down into two 2x2 boards.

To brand a cross cut on the table saw, you lot'll demand to use the miter gauge or a cantankerous cut sled. A fancy crosscut sled like this one volition allow you to brand angled cuts hands. I built my tabular array saw stand to arrange this larger sled on my jobsite table saw!

What size screws to use with 2x4 lumber

The most common screw to use with 2x4 lumber is a #9 or #ten screw that is 2 ½" long. A #ix or #10 screw is potent enough to agree 2x4 boards together without snapping under pressure level. The length will let the screw to pass completely through the first lath and almost of the style through the second, without popping out the other side.

Acquire more about how to choose the right wood screws for your project in this commodity!

Predrilling a hole in your lath will prevent the wood from splitting or cracking when you bulldoze in the spiral. If yous want the screw head to sit down beneath the surface of the wood, drill a countersink hole and use flat caput screws. You tin learn more than nigh predrilling and countersink screws hither.

If you lot're using pocket pigsty joinery, you'll need to use ii ½" Kreg screws for 2x4s. Every bit you lot can see in this cutting, the 2 ½" Kreg spiral will sit down in the pocket at the right angle to join two 2x4s together at correct angles. You tin can learn more about how to utilize a Kreg Jig here!

2x4 project ideas

At present that you know how to select, cut and screw a 2x4, yous're set up for your outset project! I have a agglomeration of 2x4 projection ideas to get y'all started!

2x4 shelving

I've built a LOT of 2x4 shelving over the years. They're super strong and can support a lot of weight, plus they're really easy to build with just 2x4s and plywood! These storage shelves are in our shed, and hold all our camping ground gear, Christmas decorations and more!

I also fabricated these smaller 2x4 garage shelves in 3 different configurations to fit the narrow space. You tin get the plans for these shelves here!

2x4 bench

You can alter the plans of this unproblematic DIY 2x4 bench to fit any space, or fifty-fifty put it exterior!

2x4 patio furniture

I've built almost all my patio furniture out of 2x4 cedar lumber! This outdoor loveseat and sofa combo fits perfectly in the corner of our deck, and was easy to put together in an afternoon.

And then I added this DIY outdoor end table, with a built in ice bucket to keep drinks cold!

Fifty-fifty this outdoor coffee table is made with 2x4s!

2x4 workbench

Once you have a few woodworking projects under your belt, you're going to want to build this 2x4 workbench to make your new hobby easier! It comes in handy as a miter saw station also.

And then what are yous waiting for? Become out to your local lumber yard or home comeback store and pick up some 2x4 boards for your next project today!

Source: https://www.thehandymansdaughter.com/2x4-lumber/

0 Response to "How To Remove Rounded Edges On 2x4"

Post a Comment