How To Repair Compression Release Valve On 10 Hp Briggs

Hullo Guys,

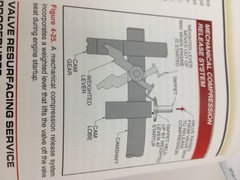

I see this thread is quite one-time at present, merely I came beyond a solution with the help of a buddy whose a modest engine mechanic. I teach modest engines at a high school, and had the "also much compression" issue in some of our 5.5hp OHV briggs engines that the students tear down, measure out and reassemble. I've fastened a couple photos from the textbook I remembered I had once the local pocket-size engine guy tipped me off well-nigh the compression release.

Many Briggs and Strattons have a compression release arrangement that relieves excess pressure during the compression stroke by releasing a small corporeality of compressed gas through either the intake valve or the frazzle.

In that location are two main ways that they reach this. The showtime is through what they telephone call an "Easy Spin" pinch release system. They apply a 2d raised side on the cam lobe to raise the valve slightly off of the seat immedietly prior to maxumum compression force per unit area. Briggs admits that they'll have to do away with this in time due to stricter and stricter emmissions testing.

The second mode, and more mutual way, is to employ a mechanical release. The ones we take at school opperate only by a weighted arm and a small bound. The issue nosotros had with too much compression was due to the little jump coming unhooked. My small engine mechanic friend said he repaired one where there was actual pieces broke off, and picked up on information technology because at that place was a chip of damage to the cam from cleaved pieces that the customer claimed were never there in the first place. (The client must take opened the crankcase, chucked the pinch release machinery, and claimed it never happened.)

If you're sure your timing is correct, every bit in you haven't had your camshaft out recently, or yous're sure it's timed correctly, then follow the following procedure:

1. set up valves correctly (make certain the piston is 1/4" downwards from TDC on power stroke, the reason it needs to be downward one/four" is to ensure that the pinch release isn't interfering with your valve lifter).

2. bank check pinch release

- Remove the spark plug

- Remove the valve cover, plough the engine flywheel clockwise while watching the valve action.

- When the Intake Valve closes, end.

- Now focus very closely on the valve spring servant of the Intake Valve, continue turning the flywheel clockwise. In about 1/4 plough, you should see the Intake Valve Retainer (and valve) make another little move towards fully closed.

- This indicates the Compression Release is working.

- IF you encounter no motility, try again.

- Still no movement, there is a problem in the Compression Release system. When the engine is common cold, you can rest the side of your hand on the head and grasp the Intake Valve Spring Retainer between yous thumb and index finger while turning every bit described and you should be able to feel the Retainer motility.

I've done a bit of searching effectually on the internet and couldn't find this solution. Hopefully it solves everyone's problems, and that your engine is sitting in the corner of your shop or garage somewhere, and hasn't been sold for scrap metal! Once more, ours was equally easy to fix equally reattaching a pocket-size leap that had become unhooked.

Source: https://www.houzz.com/discussions/1644663/briggs-stratton-won-t-start-too-much-compression

Posted by: brownsursen.blogspot.com

0 Response to "How To Repair Compression Release Valve On 10 Hp Briggs"

Post a Comment